taf-Laser

Tobias Egger, Armin Laimer, Florian Schwienbacher

- laser engraving

- laser cutting,

- 5-axis CNC-machining

- carpentry and joinery

- Realisation of individual customer ideas

- Personalised gifts

- photo engraving on wood

- design & manufacture of trophies

- promotional goods

That was a jolly evening! It was quite late on that Saturday when Tobias, who’d had a couple of beers, started to tell us about his idea for using a laser for wood processing, and we were immediately hooked. That very evening and over the next few days we batted ideas back and forth as to the correct way to tackle our idea. To keep the risks as low as possible we decided on a do-it-yourself project which we could put into practice in our spare time, alongside our existing jobs. We soon recognised the enormous potential of new laser technologies in combination with carpentry, and so we were able to turn a hobby and particular passion into a vocation. We founded taf-Laser GmbH (Ltd.) at the end of 2015. We’ve replaced our home-made laser tool with a professional device, so that the orders can be processed better.

Actually, we all three see ourselves as craftsmen. Not least, because each of us is responsible for fulfilling our orders. And that involves not just the production, but also creating the order, making contact with the clients, and much more. We also try to support and fill in for each other wherever and whenever we can. And that works just fine, we all get involved. One person’s weaknesses are an another person’s strengths. We run our company under the motto: “Together we are strong”.

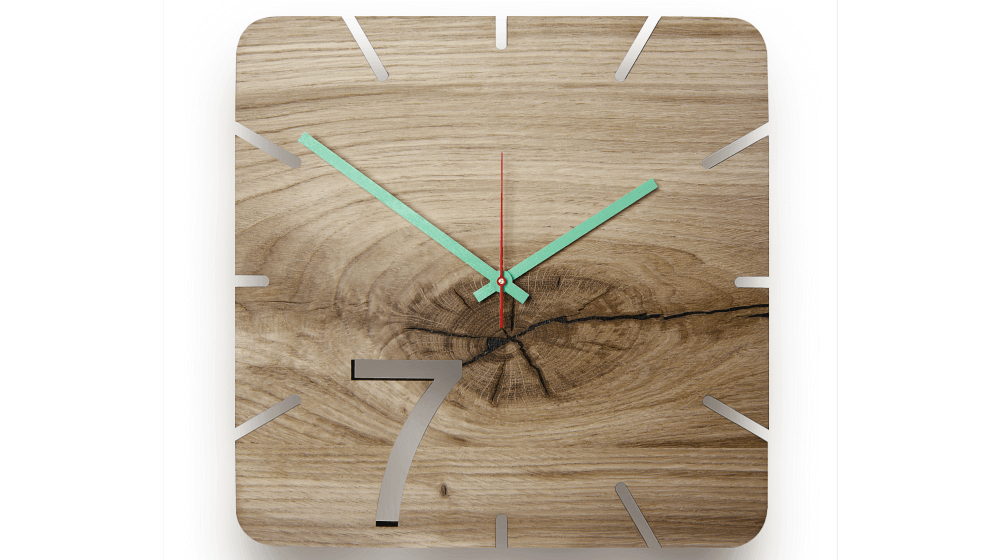

There’s always a lot of creativity bound up in craft. We love the unique nature of the work, and so we don’t just customise and embellish, but we develop and design our own products. Actually, we design practically all our wood products ourselves. Embellishing already existing wooden articles is just a fraction of our work. Most of our orders are ideas from our clients, individual requests, which we then realise and implement as best we can. These could be orders for individual items, or items for production in larger quantities. Additionally, since the end of 2015, we’ve been creating and marketing our wooden jewellery and wooden wall clocks under the label “huamet” (the local way of pronouncing the German word “Heimat”, homeland). At the end of 2017 we increased our repertoire with our high quality aromatic wooden cube with its own cube system (iDUFT, the name is based on the South Tyrol way of saying “ich dufte”, I’m fragrant). There’s been a growing trend in South Tyrol for some years now to produce cool-looking wooden objects.

We’ve often asked ourselves this same question. But we all still have the same dream: the dream of financial independence, along with a bit of prosperity. Just a few years ago it would never have occurred to us to become self-employed and it certainly never occurred to us that we would set up a business from scratch. Now we are concentrating on getting more orders and a higher profile so that we can build up our business and keep evolving. Of course we would like to grow the firm and create more jobs here in the valley over the next few years. In order to open new doors for our business and to get one step nearer to achieving our goals, we have undertaken a major investment this year – a new 5-axis CNC milling machine, acquired in March 2018, which allows to make the leap from two dimensional to three dimensional production in our product lines. Our latest investment will open new doors in the market for the manufacture of 3D products. We now have the possibility of serving new fields and lines of business. You’ll be surprised!

Contact